Innovative, energy-efficient compressed air systems cooperating with an individual analysis of the compressor systems imply enormous saving potentials regarding the required energy between 30 and 50 percent!

The topic of plant efficiency is the actual set screw to reduce consumption in the long term and sustainably, to reduce energy costs and at the same time to protect the environment through reduced CO2 emissions.

When buying a new compressed air system, the avoidably high purchase price is still the focus of the investment decision. However, an analysis of the full costs of a compressor operating at full capacity over its entire life cycle shows that energy costs account for by far the greater proportion of total costs, from 65 to 90 percent. A careful comparison of the performance data is therefore highly recommended.

– This is where we come in for you! –

An energy efficiency analysis by our experts will enable you to optimally adapt your system to the requirements of your company and to make the best possible use of available resources to increase the efficiency of your compressed air systems.

We always recommend an energy efficiency analysis

With unchanged productivity and otherwise the same conditions, your demand for compressed air will increase!?

The cause of this anomaly is leakage! Up to 30 % of the compressed air produced does not even reach the consumer, but is lost in the form of such leaks. Only about 20-30% of leaks are noticeable by hissing or other noises, the remaining 70% are not perceptible to the human ear and can only be localized with special technical equipment.

Based on the experience we have gained from our flow measurements, the potential savings range from 20 to 70 percent, depending on the company.

We make sure that your air does not go down the drain!

Scope of our leakage management

Your benefits

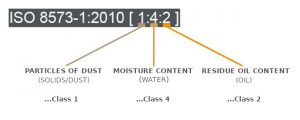

To ensure that machines and systems using compressed air can produce stably and reliably, certain requirements for the air used have been laid down in the ISO 8573-1:2010 standard. Accordingly, compressed air qualities were classified according to the degree of maximum permissible contamination.

Such defined cleanliness classes (dirt particles, moisture content, residual oil content) are particularly needed in industries that depend on compressed air quality that is individually tailored to their specific requirements.

Such demanding production takes place for example

In addition, quality measurements of the compressed air provide information on the optimum design of the downstream compressed air treatment system. For a compressed air system to run smoothly, excess humidity must be removed from the system with compressed air dryers (refrigeration, adsorption or membrane dryers) and oil and dust particles must be filtered out.

CONCLUSION: The use of compressors, filters, adsorption dryers, refrigeration dryers, etc. should be carefully planned depending on the required compressed air class.

We will be pleased to advise you on the necessary measures to optimize your compressed air quality.

Scope of quality measurement

Your benefits

An economical, energy-optimized compressed air supply is an important production and profit factor for your company and increases its competitiveness.

We therefore offer targeted in-house training courses to familiarize you with the relevant topics in the field of compressed air, such as

We will show you ways to save costs in the production of compressed air.

There is enormous energy saving potential in every compressed air station, e.g:

There are various ways to produce oil-free compressed air economically. The seminar informs about:

We are sure that the costs of compressed air supply can be effectively reduced with minimal measures.

Are you interested? Then please contact us directly.