At least as important as the removal of moisture is the removal of dirt and residual oil. This is achieved by classical filtration. The compressed air quality is classified by DIN ISO 8573-1.

ISO 8573-1 Quality classes

| Quality class | Dust particle size (mm) | max. concentration (mg/m³) | Water max. pressure dew point (°C) | Oil max. concentration (mg/m³) |

| 1

| 0,1 | 0,1 | -70 | 0,01 |

| 2

| 1 | 1 | -40 | 0,1 |

| 3

| 5 | 5 | -20 | 1,0 |

| 4

| 15 | 8 | +3 | 5,0 |

| 5

| 40 | 10 | +7 | 25 |

| 6

| – | – | +10 | – |

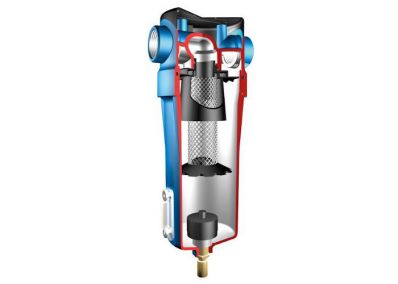

Filtration

By filtration, particles and residual oil (liquid) are filtered from the compressed air.

Regular maintenance and replacement of filter elements is essential to ensure proper functioning.

Adsorption

Adsorption is necessary to reduce the oil vapor content of compressed air.

Filter comparison

| Prefilter | Fine filter | Ultra-fine filter | Superfine filter | |

| Filter material | Sinterbronze, Phase fleece | Phase fleece | Phase fleece | Phase fleece |

| Degree of separation | 99,99 % | 99,9999 % | 99,9999 % | 99,99999 % |

| Filter fineness | 3 µ | 1 µ | 0,01 µ | 0,01 µ |

| Residual oil content | – | 0,5 mg/m³ (Liquid oil) | 0,01 mg/m³ (Liquid oil) | 0,001 mg/m³ (Liquid oil) |

| Operating overpressure | 16, 50, 350 | 16, 50, 350 | 16, 50, 350 | 16, 50, 350 |

| Nominal volume flow [m³/h] | 30 – 30.000 | 30 – 30.000 | 30 – 30.000 | 30 – 30.000 |

| Purity class according to DIN ISO 8573-1 (particles: moisture: oil) | 3:-:- | 2:-:3 | 1:-:1 | 1:-:1 |

| Application | larger quantities of solid or liquid, coarse contamination | Medium quantities of solid or liquid, fine contamination | Small quantities of solid or liquid, very fine contamination | Small quantities of solid or liquid, very fine contamination |

| Sterile filter | Activated carbon filter | Activated carbon adsorber | |

| Filter material | Phase fleece | Phase fleece vaporized with activated carbon | Activated carbon fill |

| Separation efficiency | 99,99999 % | – | – |

| Filter fineness | 0,01 µ | – | – |

| Residual oil content | – | < 0,003 mg/m³ (Oil Steam) | < 0,003 mg/m³ (Oil Steam) |

| Operating overpressure | 16, 50, 350 | 16, 50, 350 | 11, 16 |

| nominal voume flow [m³/h] | 30 – 3.500 m³/h | 30 – 30.000 m³/h | 8 – 20.420 m³/h |

| Purity class according to DIN ISO 8573-1 (particles: moisture: oil) | 1:-:1 | -:-:0-1 | -:-:0 |

| Application | microbiological organisms with the option of sterilization | Gaseous contaminants, especially oil vapor | Gaseous contaminants, especially oil vapor |