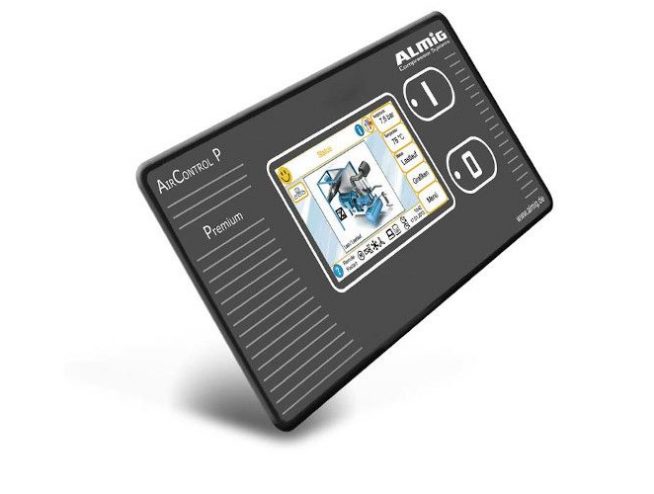

Would you like to produce your compressed air more energy-efficiently while continuing to use your existing compressors? The use of a compressor control system can always be useful if several compressors are coupled for the compressed air supply and the compressed air demand fluctuates considerably. A higher-level control system then coordinates the energy-efficient and consumption-oriented operation of the compressors.

A modern compressor control system is capable of controlling compressors of different capacities and sizes in such a way that they work together with maximum efficiency depending on the current compressed air demand.

In addition, a modern compressor control system can provide relevant data for monitoring compressor performance, utilization and efficiency. Ideally, not only the status of the compressor but also of accessory components such as dryers, condensate separators, filters, etc. is monitored.